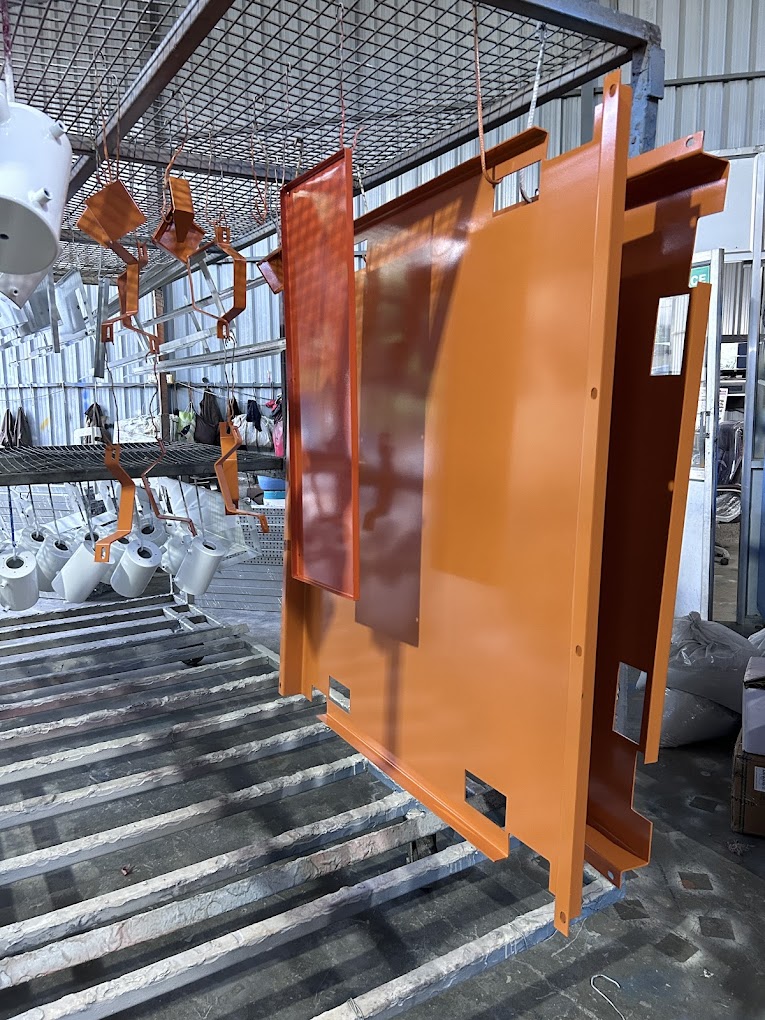

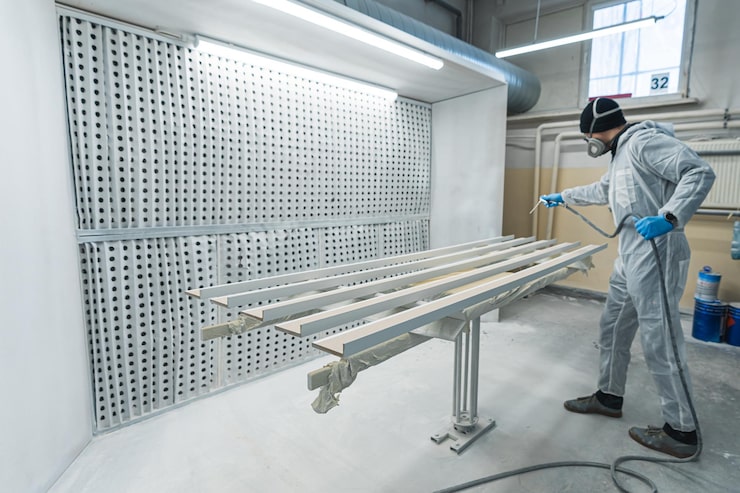

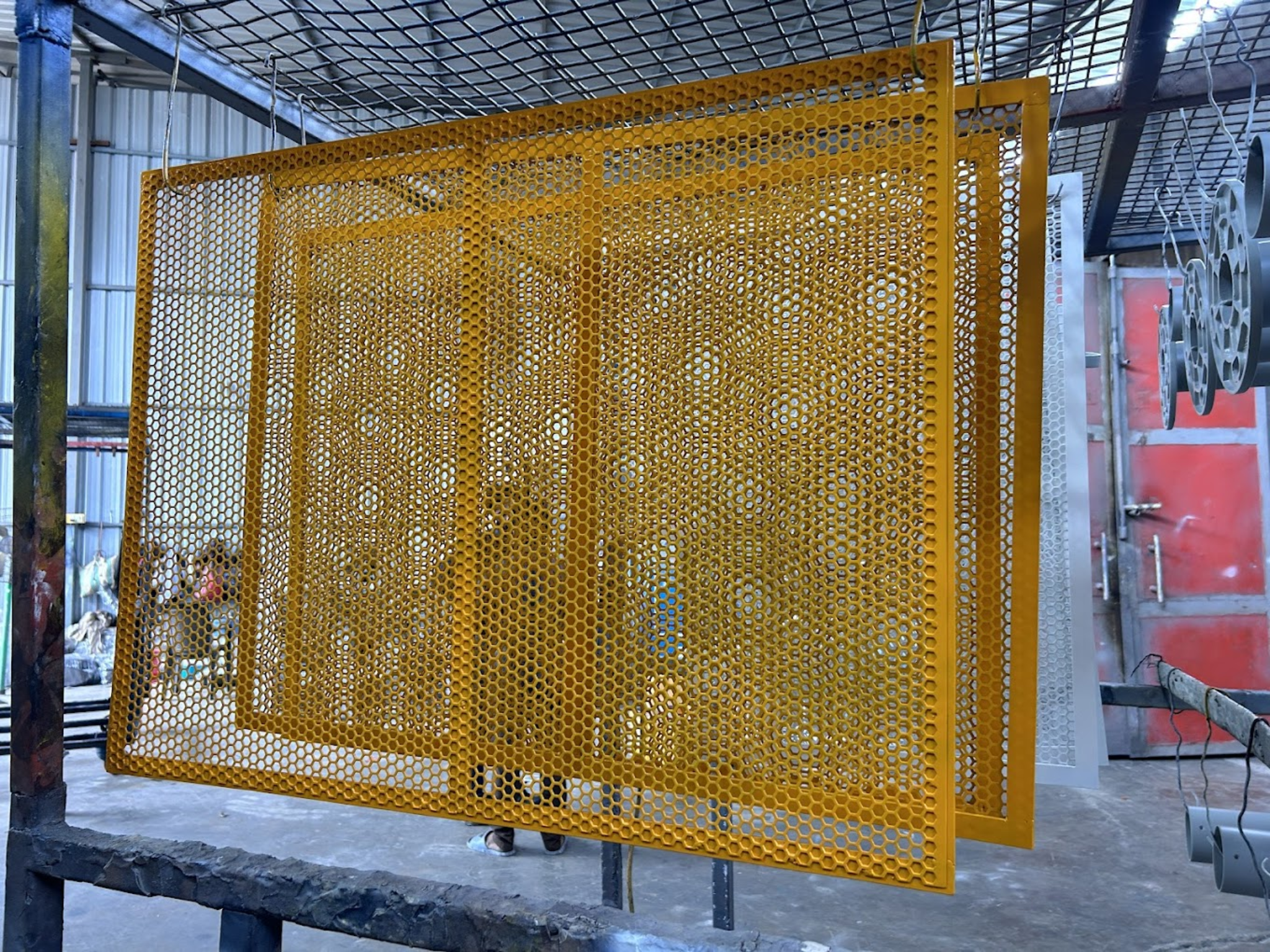

To help the powder flow over,

the metal surface

evenly.

Powder coating is a dry finishing process that has become extremely popular since its introduction in North America in the 1960s. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is applied as a free-flowing, dry powder.